Overview

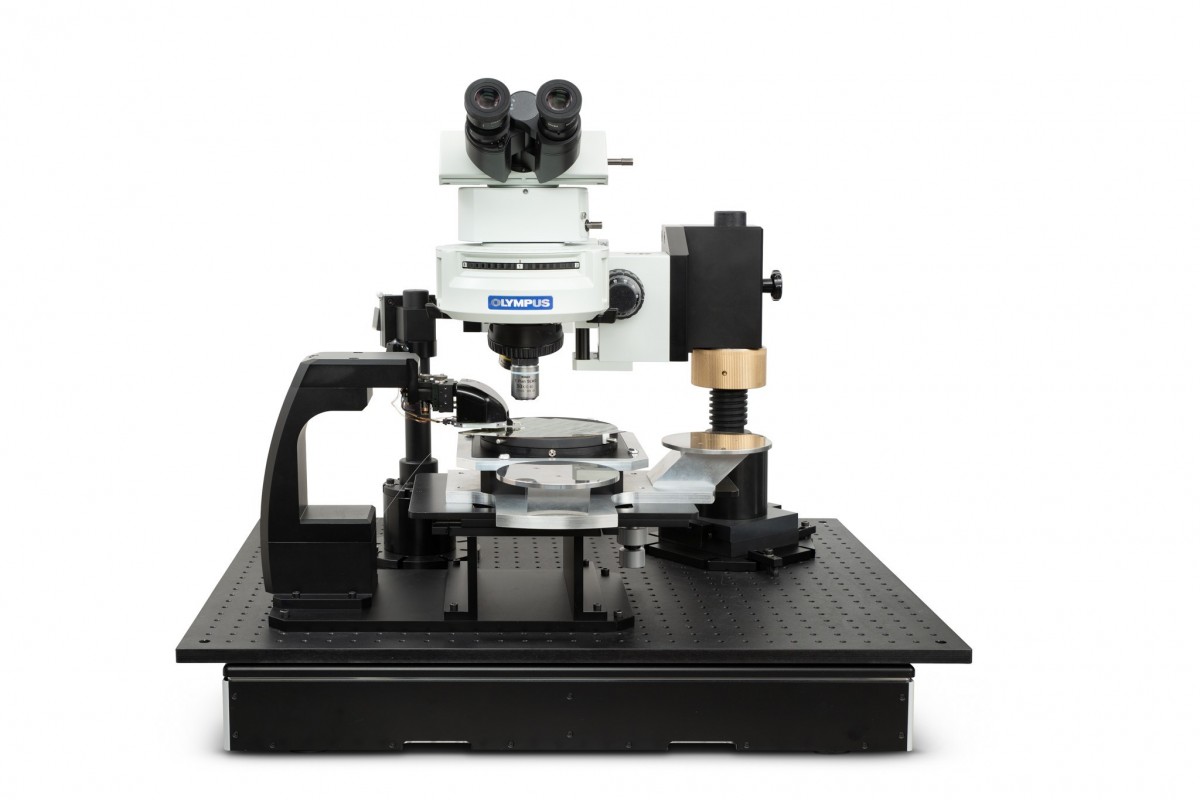

MicroLED Characterization System

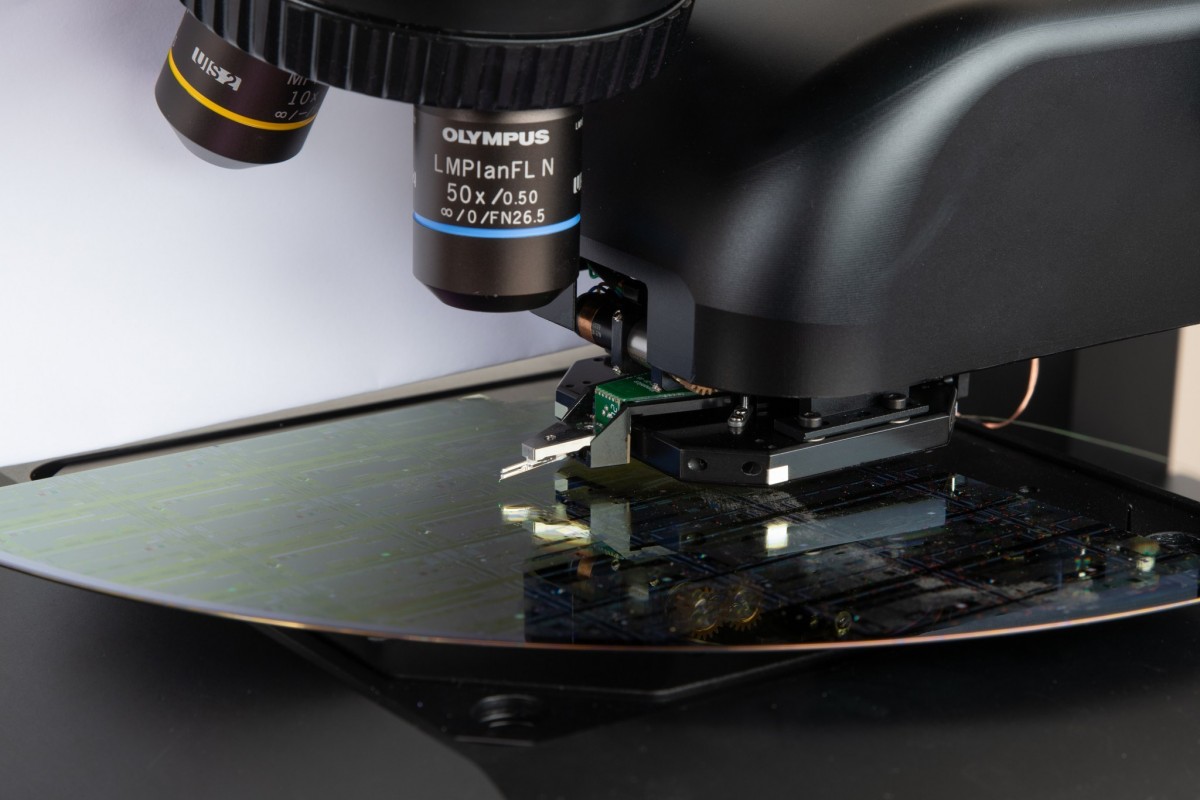

Measure- optical, spectral, and topographical properties of MicroLED pixels and defects

Map– large scale wafers for defective areas

Inspect- pixels, both with photoluminescence (PL) and electroluminescence (EL) on the nm scale

Characterize– optical, spectral, and topographical defects at the submicron scale

Correlate– optical, spectral, and topographical properties of sub-pixel features

Maintain– sample integrity – non-destructive to wafers, display panels, and pixels

InZiv is proud to present the OmniPix-ML1000TM – the first all-encompassing microLED characterization system, offering both full wafer and localized individual pixel inspection. Combining highest resolution optical measurements (both PL and EL) with spectral and topographical data, the OmniPix-ML1000TM provides a state-of-the-art solution for microLED inspection and characterization.

The OmniPix-ML1000TM integrates multiple inspection modalities in one system, and provides an unprecedented, comprehensive analysis of the pixel features. The OmniPix-ML1000TM empowers microLED developers with the ability to better understand the relationship between light, color, and structure – directly addressing some of today’s most critical challenges in microLED.

With pixels currently being developed on a scale as small as single-microns, only the highest resolution techniques can meet today’s most rigorous characterization demands. The OmniPix-ML1000 enables accurate optical and spectral characterization of individual defective, dim, and dead pixels. Using one system, you can identify irregularities in color, brightness, and structure in the microLED wafer, while subsequently examining the most problematic pixel features at the highest resolution.