Overview

Opolette 355 LD

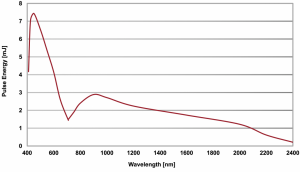

The Opolette tunable laser series utilizes optical parametric oscillator (OPO) technology to generate wavelengths over a broad range in the UV, VIS and IR. Designed for portability, the entire laserhead fits into a 7×12” footprint and ships completely sealed to protect optical components from the environment. Requiring no installation, the system includes verification hardware to check alignment after shipping or relocation. All tunable beams exit the system from the same port resulting in one beam path to the end user’s application. Wavelength tuning is motorized and computer-controlled.

Product Features

- Hermetically sealed, light-weight, compact tunable laser system

- Integrated pump laser with quick connect cables

- End-user replaceable flashlamp (50 million shot lifetime) and DI cartridge

- All tunable wavelengths output from a single port

- Alignment verification

- Computer-controlled tuning via control software/software development kit (SDK)

- Flashlamp and/or Q-Switch external triggering

- Temperature controlled, motorized Harmonic(s) (MH)

- Real-time wavelength monitoring (WM)

- Harmonic Auto-Optimization (HAO)

- Access to residual beams

- WARRANTY: One year on the entire system. Includes all options except fibers.

Product Options

- Extended UV Tuning Range (UV)

Extends tuning range to 210 – 410 nm. Decreases OPO by about 20% - External Motorized Variable Attenuator (eMVA)

End-user installable/removable. Reduces max OPO by 10-15% when installed. Computer-controlled. Can only be used with visible and near-infrared wavelengths. - Fiber Delivery Kit (FD)

Can be optimized for either ultra-violet (UV), visible (VIS), or near-infrared (NIR) tuning ranges.

Externally mounted fiber delivery kit includes mounts, coupling lens and fiber. Fiber specifications: 2.5 m long, 1 mm diameter core, NA = 0.22 - Protective Hard Shell Cases (PHSC)

Includes two protective hard cases with custom foam padding. - Extended Warranty (EXW)

Extends full system warranty for one additional year, for a total of two years. Includes all options except for fibers.